5/27/2015

Aal Chem now carries polyaspartic ester polyurea resins that work as a reactive partner with polyisocyanates to create two component polyurea/urethane clear coats.

Polyaspartic resins blend well with isocyanates for a stronger, more durable finish. The noted features they provide exterior coatings are weather and yellow resistance, zero VOCs (volatile organic compounds), and fewer coats need be applied providing greater efficiency. End-users find freedom in a fast dry time, and it can be easily applied with regular equipment even though it has a high solid content. Added advantages of using polyaspartic esters is the flexibility to design the reactivity to accommodate for batch mixing and application, control over the cure rate when added to aliphatic coatings, and the ability to change the reaction time to extend the pot-life. Basically, it can be customized to the needs of the application. The five polyaspartic ester polyurea resins in the series are detailed below.

3/19/2015

With spring upon us, we've been thinking green. As consumer concerns grow, companies are under increasing pressure to develop environmentally safer and friendlier products. Our customers come to us looking for solutions to be more conscious of the environment without sacrificing the integrity of their products. For instance, a mix of PCBTF (our Oxol-100) along with methyl acetate can create zero VOC paints.

Did you know that some of our suppliers offer non-hap, low VOC, waterborne, as well as other products that are environmentally friendly or considered green?

3/18/2015

Supplier Shanghai Pioneer (PSA) is the largest acrylic resin manufacturer in Asia for coatings. With strong R&D capacity, PSA is excellent in custom tailored formulas and scale up production for innovative and specialty products for our customers. Applications for their products include: paints and coatings, marine and automotive, architectural and industrial, adhesives, inks, clothing, ceramics, everyday household items, and other various industries.

1/30/2015

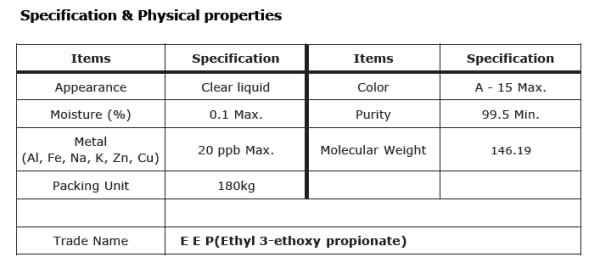

With its slow-evaporating capabilities, ethyl 3-ethoxy propionate (EEP, CAS No. 763-69-9) is an ideal ether-ester solvent for a vast range of coatings. EEP can be used as a solvent retarder in high-performance bake and air-dried coatings.

10/28/2014

Zinc Phosphate is a principal raw material that gives paints and coatings anti-corrosive properties. Originally, zinc phosphate was used as a non-toxic alternative to zinc chromate and red lead. It is used in anti-corrosive paint primer systems, especially those based on solvent borne Epoxy-Polyamide, Chlorinated rubber, Alkyd and Polyurethane resins and water based systems. Delaphos is the only zinc phosphate producer in the UK. They offer the purest white phosphate with no yellowing and high opacity in the following four grades: