5/27/2015

Polyaspartic Resins Deliver Durable Coatings

Aal Chem now carries polyaspartic ester polyurea resins that work as a reactive partner with polyisocyanates to create two component polyurea/urethane clear coats.

Polyaspartic resins blend well with isocyanates for a stronger, more durable finish. The noted features they provide exterior coatings are weather and yellow resistance, zero VOCs (volatile organic compounds), and fewer coats need be applied providing greater efficiency. End-users find freedom in a fast dry time, and it can be easily applied with regular equipment even though it has a high solid content. Added advantages of using polyaspartic esters is the flexibility to design the reactivity to accommodate for batch mixing and application, control over the cure rate when added to aliphatic coatings, and the ability to change the reaction time to extend the pot-life. Basically, it can be customized to the needs of the application. The five polyaspartic ester polyurea resins in the series are detailed below.

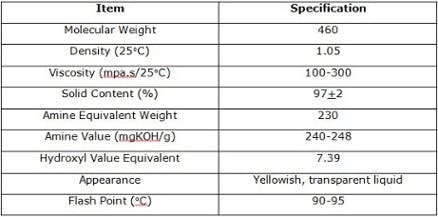

F420

F420 offers a high solid content with low viscosity and a fast cure time in an aliphatic system. It can serve as a chain extender or R component in polyurea coating. It can also react with –NCO functional HDI trimmer from which a longer gelling time and excellent yellow resistance can be achieved. Longer gelling time can also be obtained when reacted with MDI pre-polymer. A hybrid of polyurea and polyurethane can be achieved when F420 is blended with hydroxyl-functional resin e.g acrylic, alkyd. It has a pot life of 35 minutes.

Chemical Name: Aspartic Acid, N,N'-(methylenedi-4,1-cyclohexanediyl)bis-,1,1',4,4'-tetraethyl

ELINCS No.: 429-270-1

CAS No.: 136210-30-5

F420 can be used for any weather and saline water resistant coating application such as automotive, anti-corrosion, exterior walls, and flooring, including concrete.

Additional benefits:

Quick cure rate in aliphatic system

Long Lasting coats

Versatile usage

Quick dry coatings

Anti-Corrosion and anti-abrasion

Offers faster dry time than regular polyurethane coatings

Prevents bubbling because of faster dry rate

High film build

Amine-functional and solvent free

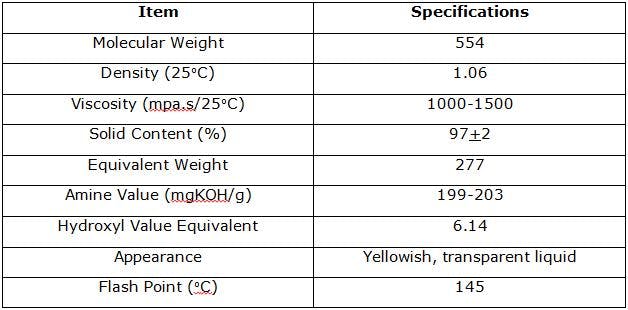

F520

F520 creates a coat with high solid content and low viscosity. It can also react with –NCO functional HDI trimmer from which a longer gelling time and excellent yellow resistance can be achieved. Longer gelling time can also be obtained when mixing with F-420 and F-524 to achieve a pure aspartic polyurea coating with high build and fast dry two pack coating system. The F-520 is also compatible with other hydroxyl-functional resin e.g acrylic, alkyd. The pot life is 120 minutes.

Chemical Name: Aspartic Acid, N,N'-[methylenebis(2-methyl-4,1-cyclohexanediyl)]bis-,

1,1',4,4'-tetraethyl ester

ELINCS No.: 412-060-9

CAS No.: 136210-32-7

F520 is used as weather and yellow resistant coating for floors, automotive, concrete, and exterior walls.

F220

Due to its extremely low viscosity, F220 is used to create spray coatings that are extremely flexible. The pot life is 5 minutes.

F220 is specialized for spray coating that specifically works well on plastics and metals and creates a highly flexible coat. It is most effectively used to protect steel beams and different types of pipes from corrosion and the wear and tear of weather and water damage. Industries include plastic and metal anti-corrosion coating.

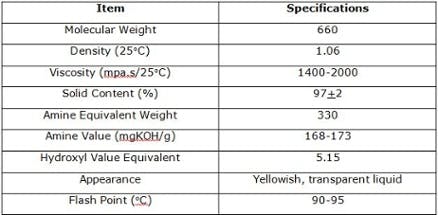

F524

F524 is similar to F420, but offers longer gelling time than F420 and shorter gelling time than F520. It has a high solid content with low viscosity and higher flexibility than F420. The pot life is 45 minutes.

The main applications are in waterproof coating, weather resistant and flooring coatings.

Additional benefits:

Fast Cure time

Weather and Water Resistant

High hardness, flexibility, elongation and tear and tensile strength

Prevents bubbling in coating because of faster dry rate

High film build

Amine-functional and solvent free

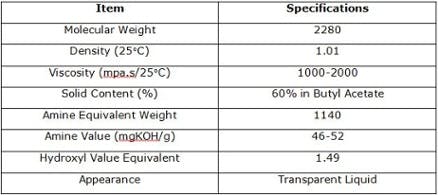

D2925

D2925 is a polymerized version of the F420 polyaspartic resin. It is the only resin in the series that is solvent based. D2925 is often reacted with a solvent based polyisocyanate to formulate a two component polyurea/urethane coating. The pot life is 40 minutes.

This is a specific product that can be used to make coatings very weather resistant, anti-abrasive, and anti-corrosive. It is primarily used with a solvent based IPDI-Trimer to formulate an outdoor waterproof coating that can be used on concrete outdoors as well as exterior topcoats on cars. D2925 is used in applications that require coating in drastic weather and water conditions, most specifically the automotive industry and outdoor floor coating.

Each of these products must be stored in a tightly sealed drum to prevent moisture exposure. The shelf life is 12 months at 25 degrees Celsius (77oF). Packaging is in 440.9lbs drums or 44.09lbs pails with recommended storage at 0oC-40oC (32oF-104oF) temperature.

Please contact us to request data sheets, samples, pricing, or to provide more information.

Topics: Automotive, Construction, Solvent Free, Paints and Coatings, Weather Resistant,Moisture Resistant, Anticorrosion, Flooring, Low to No VOC, Yellow Resistant, Environmentally Friendly, Abrasion Resistant, Chemical Resistant, Plastics